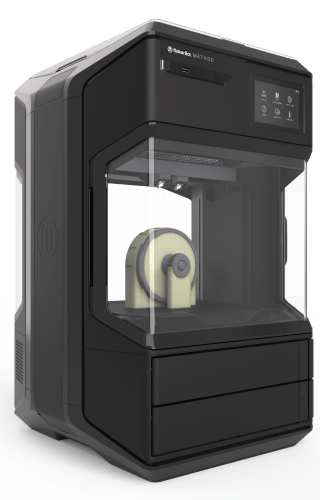

MakerBot will save your business engineering time with our printer’s Automated Workflow and CAD Integration, characteristics that elevate the superior mechanical and thermal properties far above modified desktop 3D printer formulations. MakerBot’s 3-D printer is the only instrument on the current market that combines advanced materials and a heated chamber to achieve dimension accuracy (± 0.2mm (± 0.007in) and stronger manufacturing-grade parts. The innovative technology used in MakerBot 3-D printing recirculates heat throughout every layer of the printing process, accomplishing consistent strength and reliability in its products.

Our printer’s SR-30 soluble support allows for the efficient and quality production of 25 compatible materials. Access unlimited materials such as Nylon Carbon Fiber, ABS, Nylon, PC-ABS and SR-30 with an Open Materials Platform. Promote the printing capabilities of your workplace with advanced material production, such as ABS Carbon, TPE (flexible), PETG ESD, and PC.

The engineering team behind MakerBot’s 3-D printing technology have developed highly customised tooling solutions to assist your workplace in a wide array of production and design commissions. All Axis Engineers consistently choose our professional-grade printing technology for the competitive production costs and tinker-free industrial aptitude.